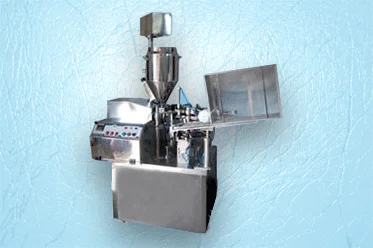

Fully Automatic Aluminium Tube Filling,

Crimping, and Coding Machine

Automatic tube filling machine executes filing, crimping and batch coding functions. It is easier to achieve different filing speeds through the 8/12 station divergent which are positioned in this type of machine. This machine has a rotary structure made from heavy casting materials for accurate working. The crimping part is taken care by the station for perfect sealing applications. This is done with two stages of crimping i.e. normal and saddle fold crimping. All the actions performed in the machine are done automatically without touch of hands.

We are manufacturers, suppliers and exporter of one of the best quality automatic aluminum tube filing, crimping and coding machines. The electronic controller on the machine is used to control the water temperature and this action gets displayed on the front panel of the station. We manufacture customized machines as per the specifications and dimensions received from our customers. Our customer friendly approach has helped us to come a long way in maintaining cordial relations with them. The automatic tube filing machine manufactured by us is used in varied industries like pharmaceutical, chemicals food processing, solvents, cosmetics and also by industries using viscous and semi viscous materials such as adhesives. Some of the salient features of our automatic machine can be briefed as under:

Salient Features- ➤ Our machine occupies less space due to the cylindrical round shape structure. It can easily be established even in a smaller area.

- ➤ We have added the component of no tube no fill as a result of this aspect there is zero or minimum wastage of any materials.

- ➤ The machine has a vertical dosing system that helps in easy suction of materials.

- ➤ The batch code system is offered with the machine.

- ➤ It is completely an operator friendly machine with very simple mechanism.

- ➤ Easy cleaning system through the air blowers.

- ➤ Auto Feeding & Orientation of tubes with "I" mark Sensor.

- ➤ Contact parts made of S.S 304/S.S 316L. Quality material that confirms to CGPM Norms.

- ➤ LEISTER make Hot air tools for Lami Tube Sealing.

- ➤ Quickly change over from Lami to aluminum tubes within 10 to 15 minutes.

- ➤ Production counter available on control panel to indicate number of tubes filled.

- ➤ Filling Accuracy + 1 %

- Optional Item ot Attachment:

- ➤ Jacketed hopper & stirrer.

- ➤ Tube cleaning Attachment.

- ➤ Hopper level sensor.

- ➤ Transfer Pumps.

- ➤ Nitrogen Purging.

- ➤ Plc Control.

Filling speed for aluminum |

30 to 40 tube per/min |

Filling range |

5 to 150 gm interchangeable syringe and piston |

Tube size |

Min. Dia - 12 to 35 mm, length - 70 to 180 mm |

Operator require |

One operator |

Power consumption |

3 Kw. |

Compressor air |

6 to 7 kg/PSI |

Net weight |

400 Kg. |

Gross weight |

450 Kg. |

Dimension |

L - 60", W - 32", H - 86" |